Central hydronic air conditioning systems are also called central air conditioning systems. In a central hydronic air conditioning system, air is cooled or heated by coils filled with chilled or hot water distributed from a central cooling or heating plant. It is mostly applied to large-area buildings with

many zones of conditioned space or to separate buildings.

Water has a far greater heat capacity than air. The following is a comparison of these two media

for carrying heat energy at 68°F (20°C)

The heat capacity per cubic foot (meter) of water is 3466 times greater than that of air. Transporting heating and cooling energy from a central plant to remote air-handling units in fan rooms is

far more efficient using water than conditioned air in a large air conditioning project. However, an

additional water system lowers the evaporating temperature of the refrigerating system and makes a

small- or medium-size project more complicated and expensive.

A central hydronic system of a high-rise office building, the NBC Tower in Chicago, is illustrated in Fig. 1.1. A central hydronic air conditioning system consists of an air system, a water

system, a central heating/cooling plant, and a control system.

Air System

are the air-handling units, supply/return ductwork, fan-powered boxes, space diffusion devices, and

exhaust systems.

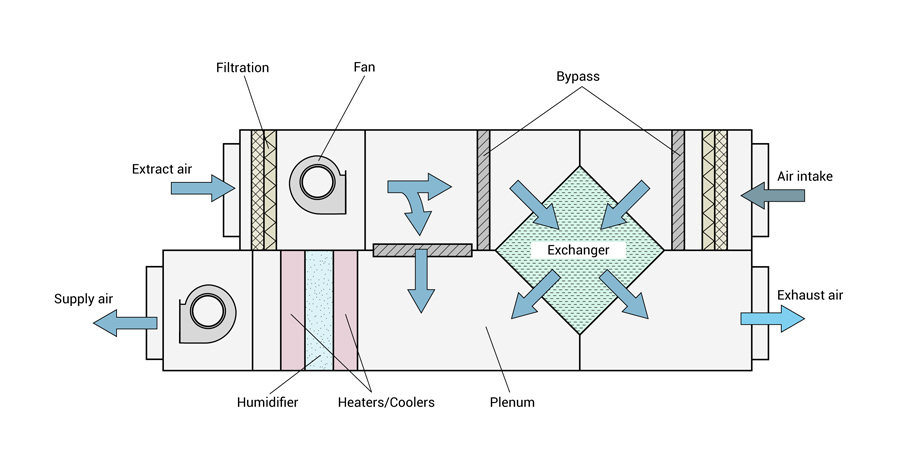

An air-handling unit (AHU) usually consists of supply fan(s), filter(s), a cooling coil, a heating

coil, a mixing box, and other accessories. It is the primary equipment of the air system. An AHU

conditions the outdoor/recirculating air, supplies the conditioned air to the conditioned space, and

extracts the returned air from the space through ductwork and space diffusion devices.

A fan-powered variable-air-volume (VAV) box, often abbreviated as fan-powered box, employs

a small fan with or without a heating coil. It draws the return air from the ceiling plenum, mixes it

with the conditioned air from the air-handling unit, and supplies the mixture to the conditioned

space.

Space diffusion devices include slot diffusers mounted in the suspended ceiling; their purpose is

to distribute the conditioned air evenly over the entire space according to requirements. The return

air enters the ceiling plenum through many scattered return slots.

Exhaust systems have exhaust fan(s) and ductwork to exhaust air from the lavatories, mechanical rooms, and electrical rooms.

The NBC Tower in Chicago is a 37-story high-rise office complex constructed in the late 1980s.

It has a total air conditioned area of about 900,000 ft2 (83,600 m2

). Of this, 256,840 ft2 (23,870 m2

)

is used by NBC studios and other departments, and 626,670 ft2 (58,240 m2

) is rental offices located

on upper floors. Special air conditioning systems are employed for NBC studios and departments at

the lower level.

For the rental office floors, four air-handling units are located on the 21st floor. Outdoor air

either is mixed with the recirculating air or enters directly into the air-handling unit as shown in

Fig. 1.2. The mixture is filtrated at the filter and is then cooled and dehumidified at the cooling coil

during cooling season. After that, the conditioned air is supplied to the typical floor through the

supply fan, the riser, and the supply duct; and to the conditioned space through the fan-powered box

and slot diffusers

Water System

The water system includes chilled and hot water systems, chilled and hot water pumps, condenser

water system, and condenser water pumps. The purpose of the water system is (1) to transport

chilled water and hot water from the central plant to the air-handling units, fan-coil units, and fan powered boxes and (2) to transport the condenser water from the cooling tower, well water, or other

sources to the condenser inside the central plant.

In Figs. 1.1 and 1.2, the chilled water is cooled in three centrifugal chillers and then is distributed to the cooling coils of various air-handling units located on the 21st floor. The temperature of

the chilled water leaving the coil increases after absorbing heat from the airstream flowing over the

coil. Chilled water is then returned to the centrifugal chillers for recooling through the chilled water

pumps.

After the condenser water has been cooled in the cooling tower, it flows back to the condenser of

the centrifugal chillers on lower level 3. The temperature of the condenser water again rises owing

to the absorption of the condensing heat from the refrigerant in the condenser. After that, the condenser water is pumped to the cooling towers by the condenser water pump.

Central Plant

The refrigeration system in a central plant is usually in the form of a chiller package. Chiller packages cool the chilled water and act as a cold source in the central hydronic system. The boiler plant,

consisting of boilers and accessories, is the heat source of the heating system. Either hot water is

heated or steam is generated in the boilers.

In the NBC Tower, the refrigeration system has three centrifugal chillers located in lower level 3

of the basement. Three cooling towers are on the roof of the building. Chilled water cools from 58

to 42°F (14.4 to 5.6°C) in the evaporator when the refrigerant is evaporated. The refrigerant is then.

compressed to the condensing pressure in the centrifugal compressor and is condensed in liquid

form in the condenser, ready for evaporation in the evaporator.

There is no boiler in the central plant of the NBC Tower. To compensate heat loss in the perimeter zone, heat energy is provided by the warm plenum air and the electric heating coils in the fan powered boxes.

Control System

Modern air conditioning control systems for the air and water systems and for the central plant consist of electronic sensors, microprocessor-operated and -controlled modules that can analyze and perform calculations from both digital and analog input signals, i.e., in the form of a continuous variable.

Control systems using digital signals compatible with the microprocessor are called direct digital

control (DDC) systems. Outputs from the control modules often actuate dampers, valves, and relays

by means of pneumatic actuators in large buildings and by means of electric actuators for small

projects.